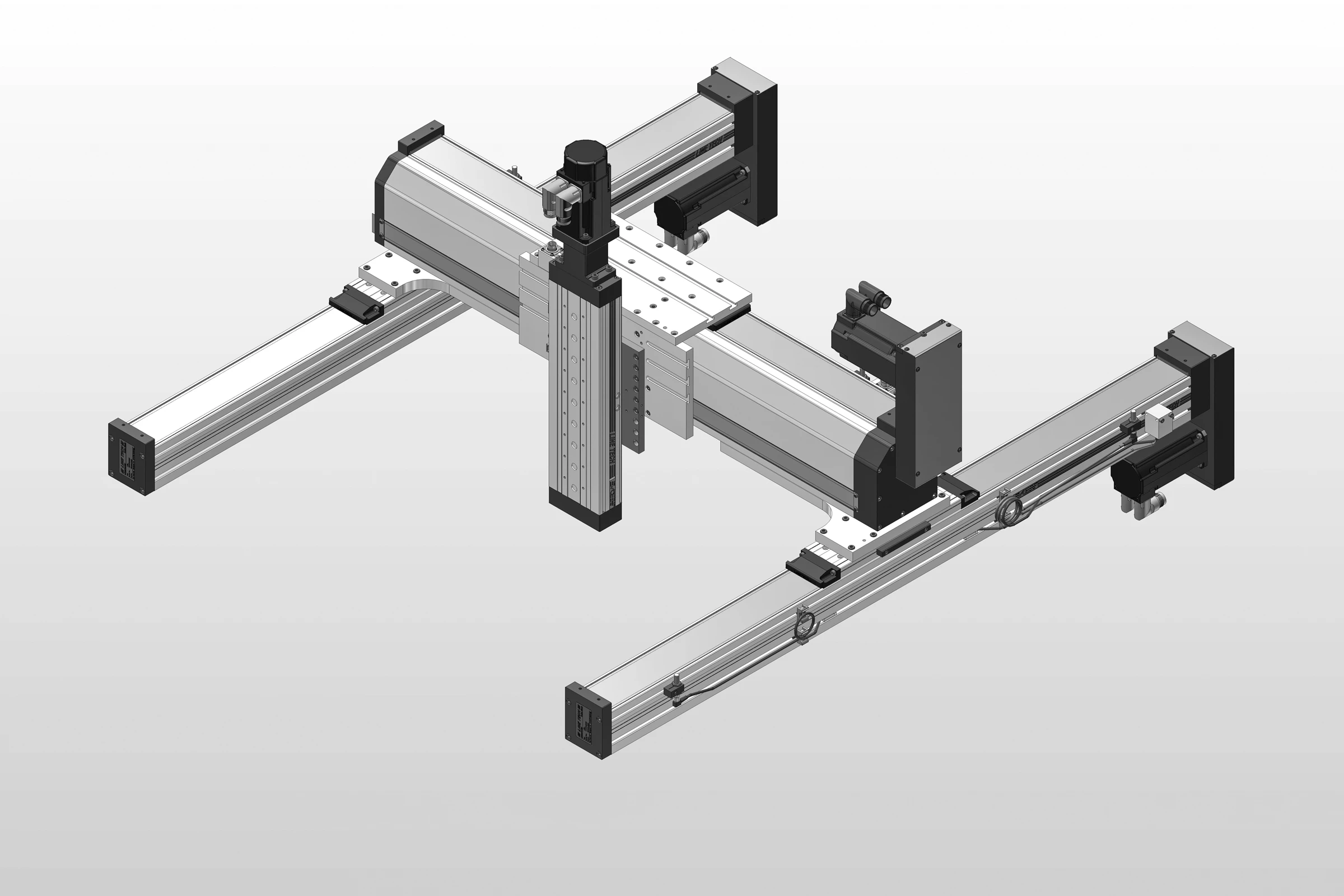

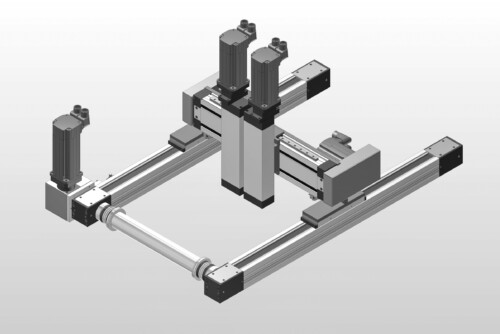

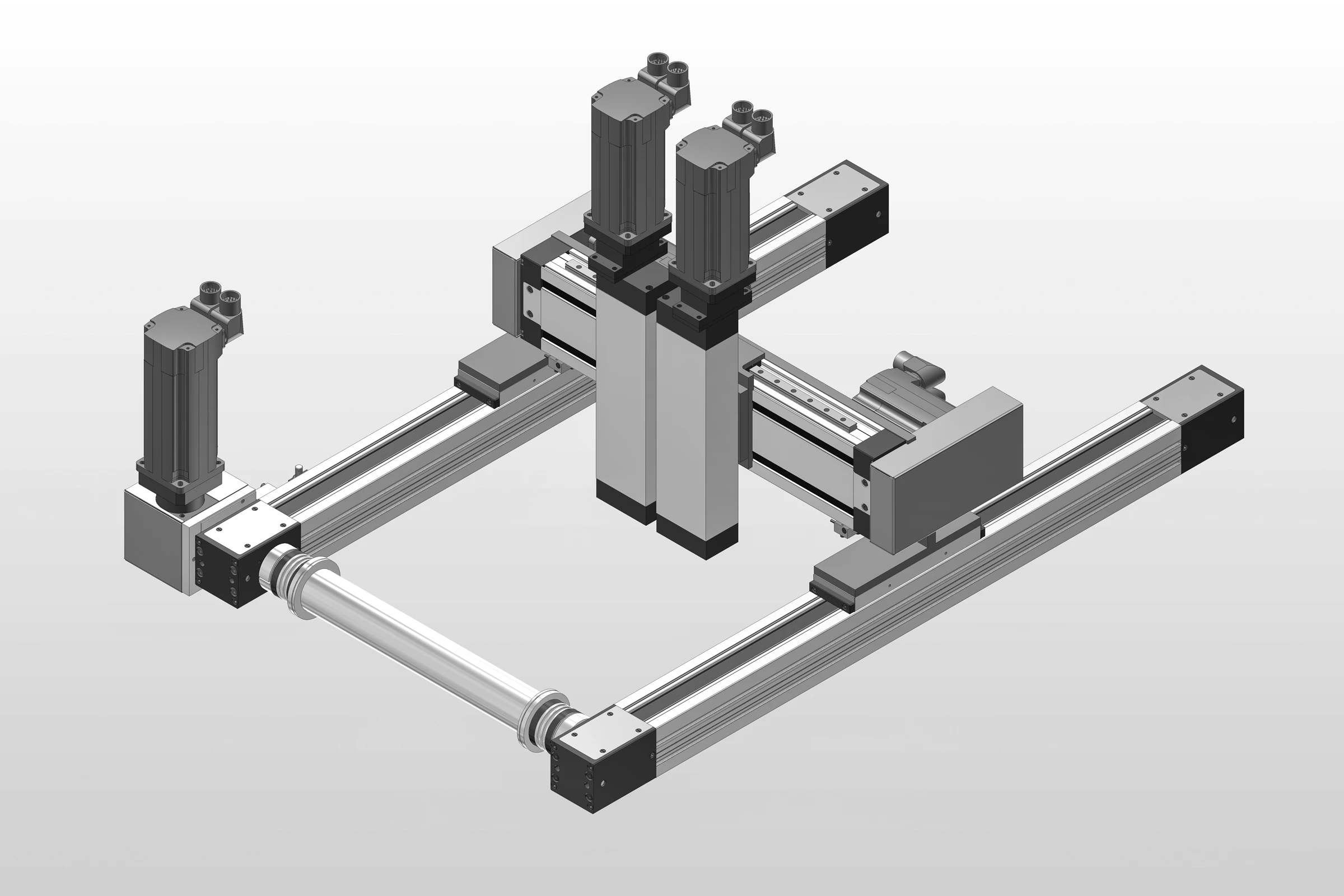

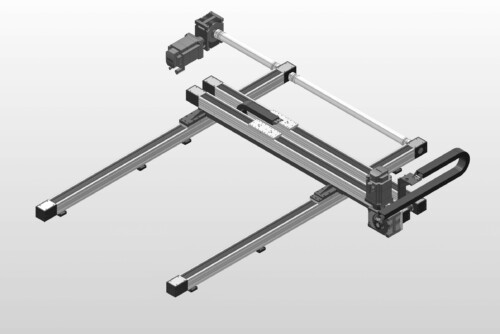

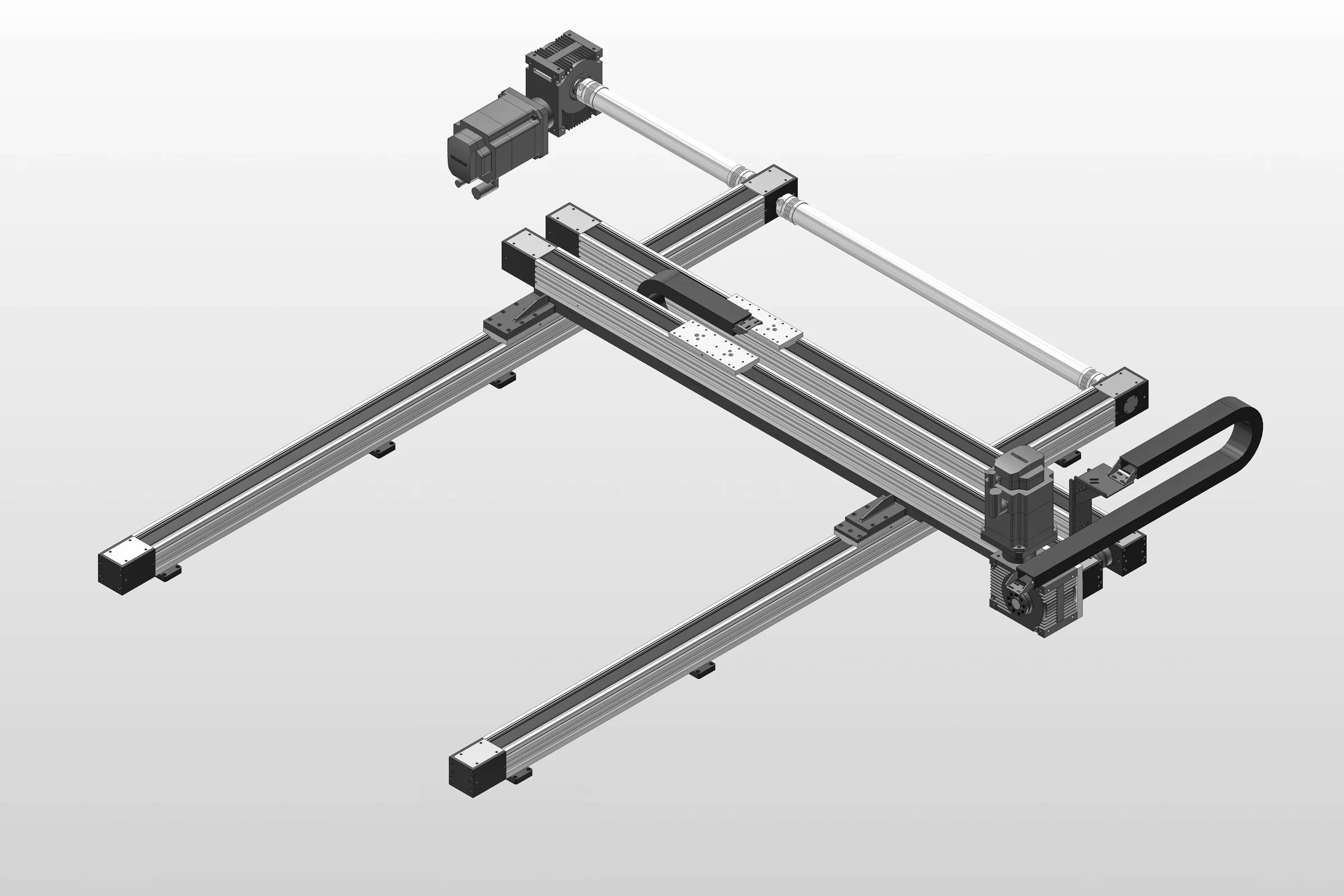

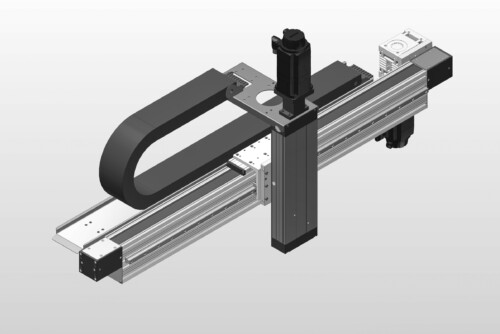

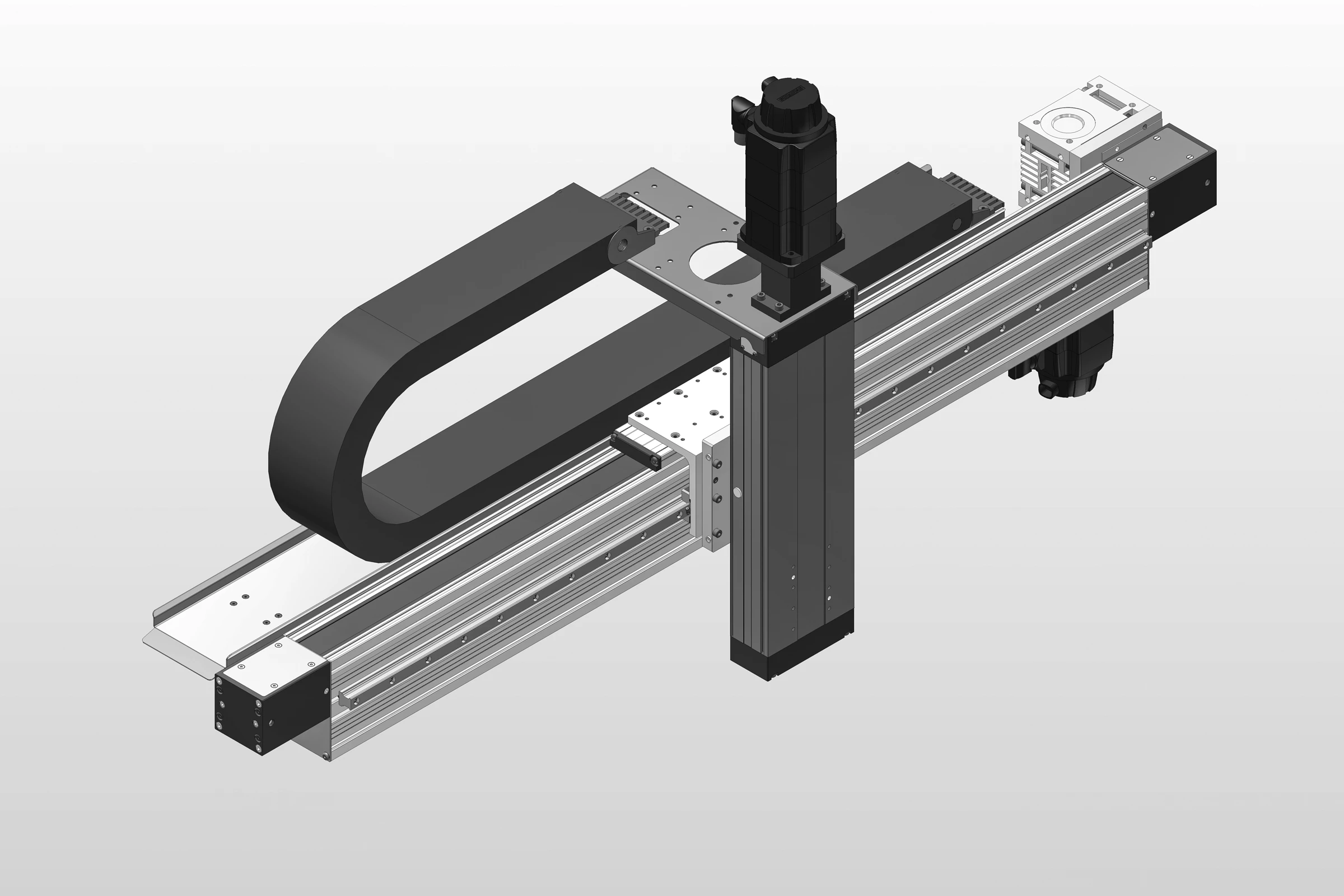

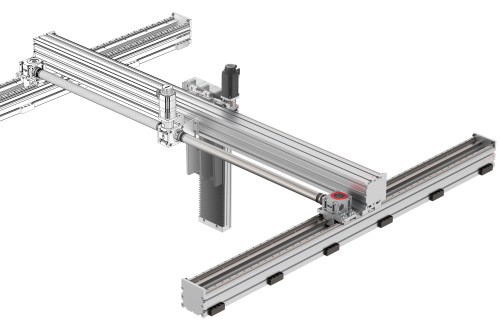

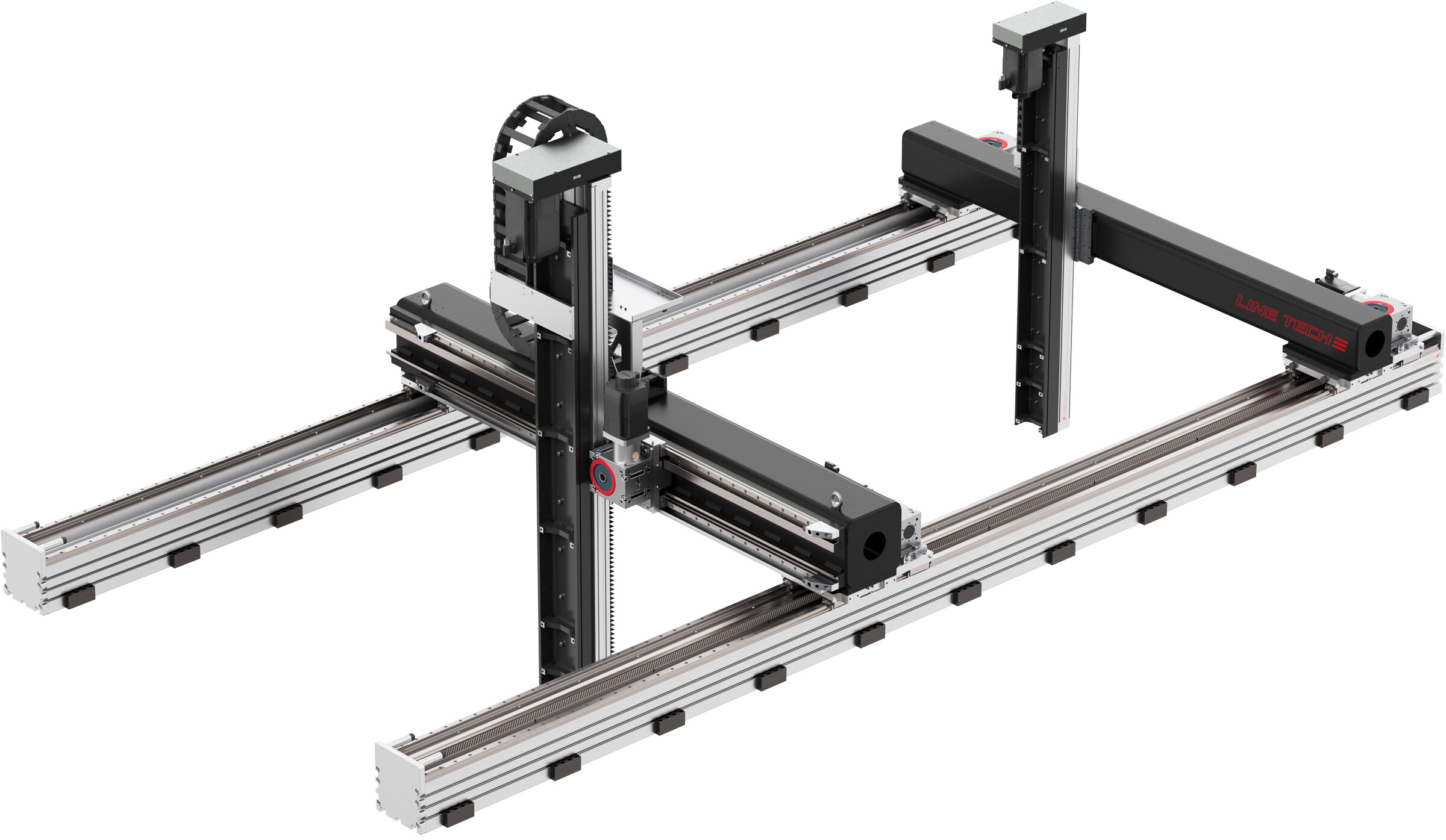

Linear system solutions from a single source: Consulting – Engineering – Manufacturing

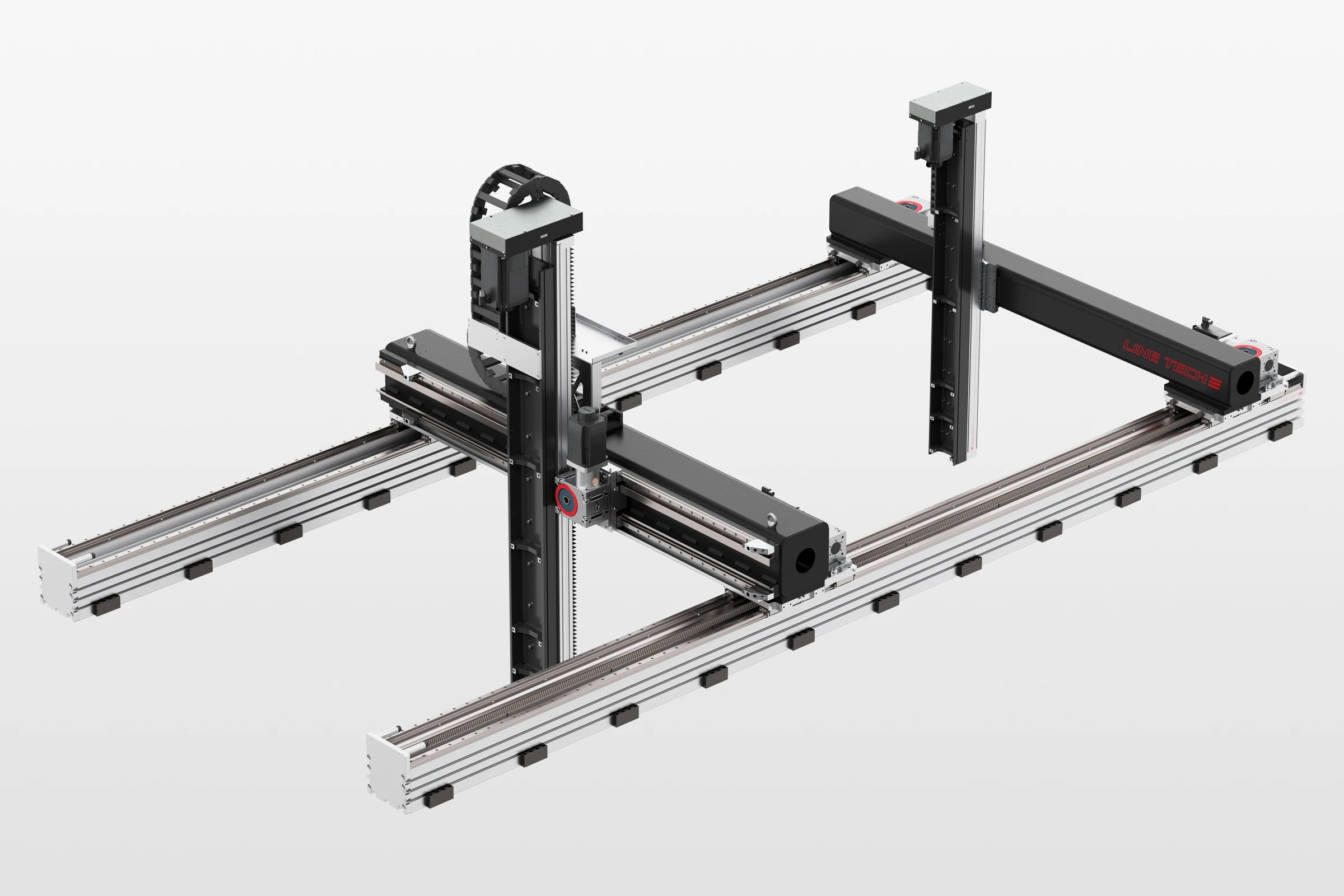

Linear movement is the backbone of modern industrial production systems. In addition to the in-house development and production of linear axes, LINE TECH specializes in the conception, design and manufacture of multi-axis system solutions. Since 1993, we have been supporting our customers with engineering services and supplying application-specific optimized linear systems for a wide range of functions » LINE TECH Product Range (PDF)

Consulting – Expert advice for customised solutions

Our experienced consulting team will support you from the initial idea through to implementation. We analyse your specific requirements and work with you to develop tailor-made concepts. Thanks to our short communication channels and close cooperation with engineering and production, we guarantee a fast, smooth process and maximum transparency in all project phases.

Engineering – Systematic development: Fast. Flexible. Customer-oriented.

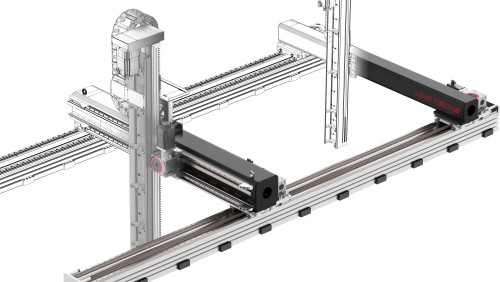

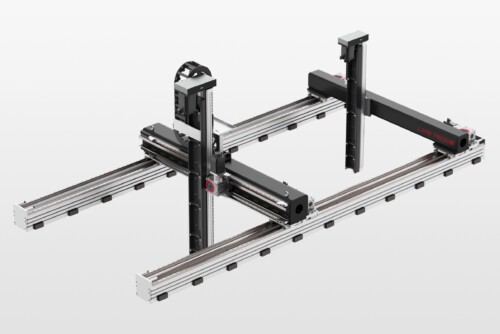

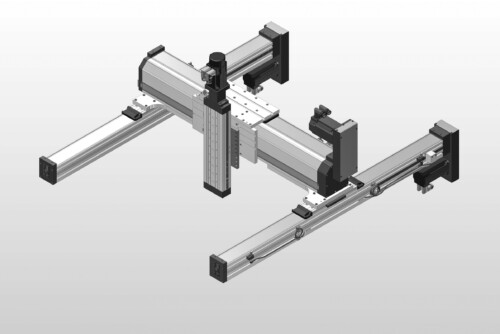

With our modular development approach and an experienced team, we implement specific customer requirements efficiently and reliably. Even for complex requirements such as confined spaces, high forces or particularly long travel distances, we develop individual solutions – always with the aim of providing you with an optimal and durable product. Through the direct integration of consulting, engineering and production, we guarantee a smooth process and the highest quality – all from a single source.

Manufacturing – made in-house in Glattbrugg

Thanks to our in-house production, we guarantee the fastest possible availability, maximum flexibility, high precision and top quality.

Profile machining up to 9 metres – precision in a new dimension

With our state-of-the-art 5-axis machining centre – the longest in Switzerland – we at LINE TECH are setting new standards in profile machining. We machine aluminium with the highest precision, efficiently and entirely according to your individual requirements, in lengths of up to 9 metres in one piece.

Whether complex geometries, sophisticated special solutions or series production: our technologies open up new possibilities for your parts – with maximum flexibility, cost-effectiveness and the shortest response times.

Systematic assembly: efficient – modular – sustainable

At LINE TECH, we assemble modules and complete systems directly at our site in Glattbrugg – quickly, precisely and in accordance with the principles of lean management. Thanks to short distances and streamlined processes, we guarantee highly efficient production of the highest quality..

Our own products are modular, bolted together and can be dismantled at any time. This not only makes them particularly easy to maintain, but also sustainable and reusable. Whether individual modules or complete assemblies: we deliver tailor-made solutions for all areas of automation.

Logistics – from ordering to JIT delivery

In our fast-paced world, speed is everything. Thanks to our streamlined organisation with efficient processes, we always deliver in the shortest possible time – and just-in-time if required.

After-sales service

Even after delivery, we remain your reliable partner.

As a reliable service provider for overhauls, repairs and express modifications, LINE TECH also supports its customers directly on site. Fast, flexible and solution-oriented – exactly when it matters. And, if necessary, with ‘overnight operations’ too...

Whether mechanical commissioning, short-term adjustments or technical support during ongoing operation: our experienced team will accompany you throughout the entire service life of your systems. With our after-sales service, we offer you maximum security and short response times: competent, personal and always ready to help – because good service does not stop when the product is delivered.