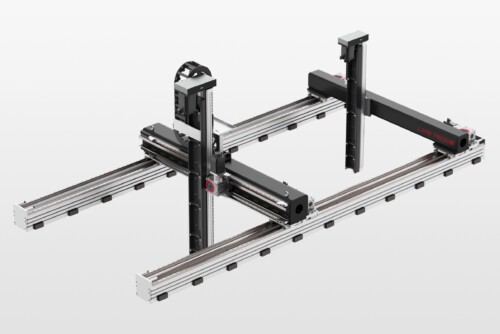

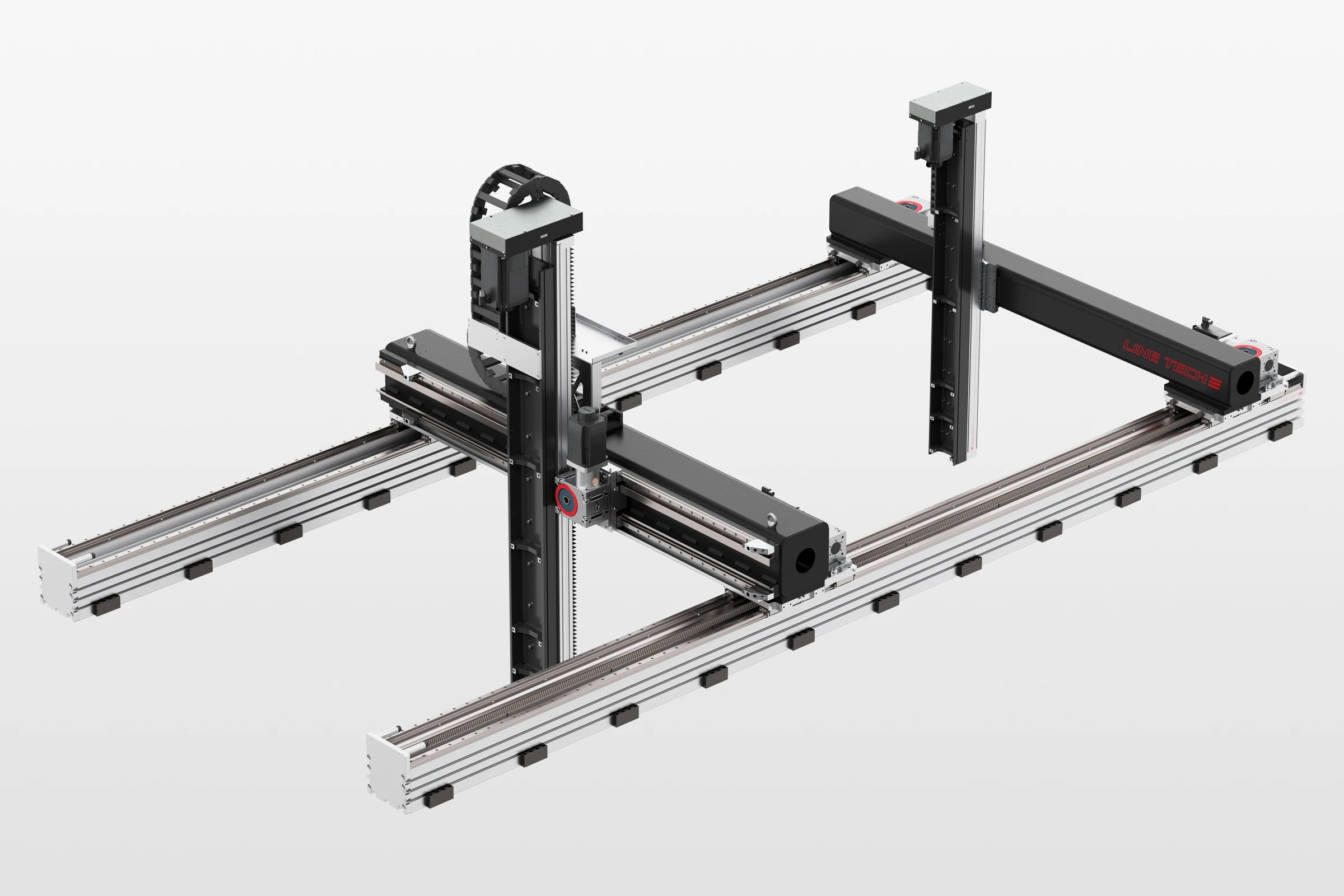

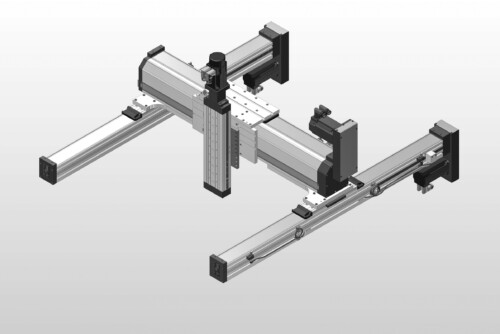

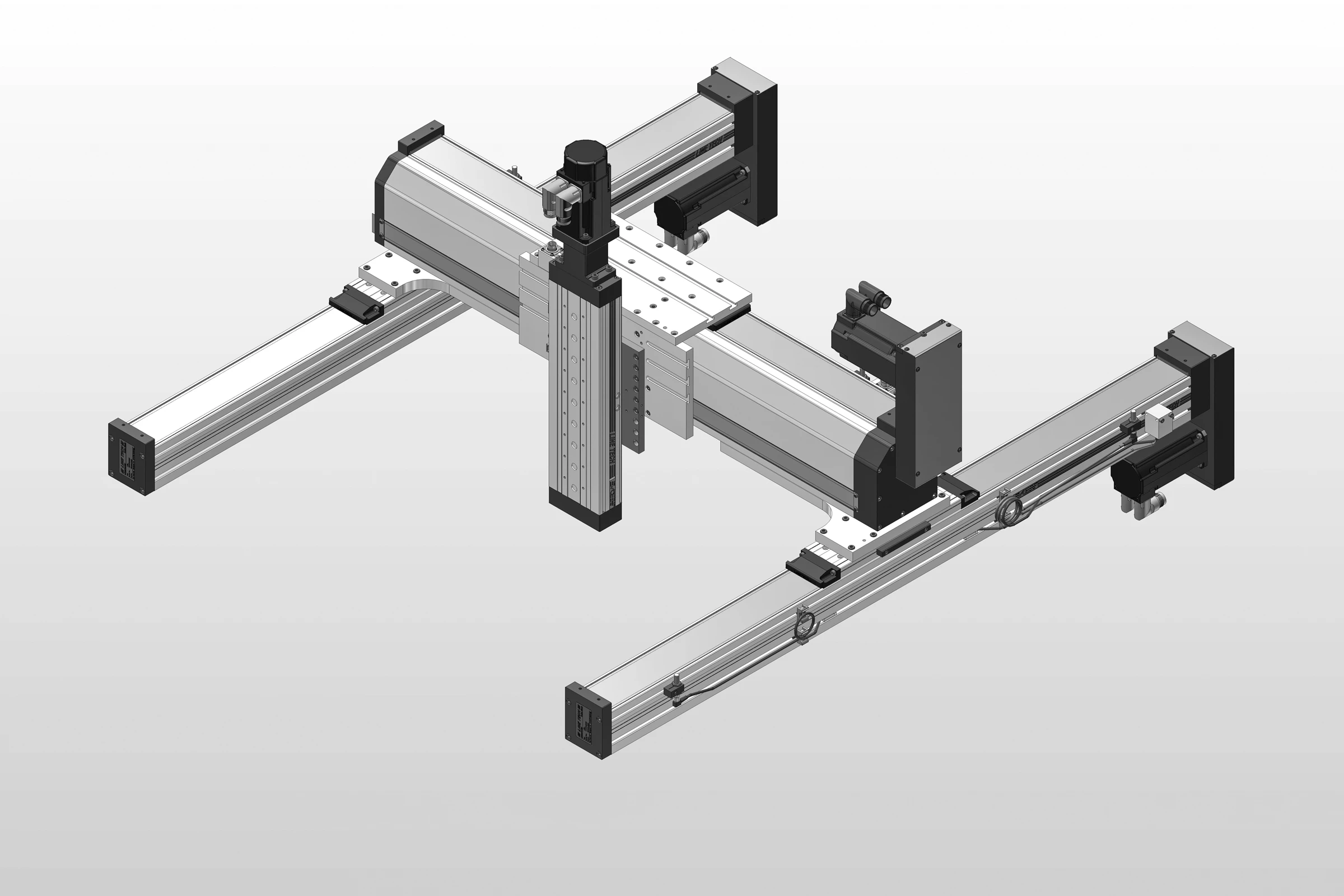

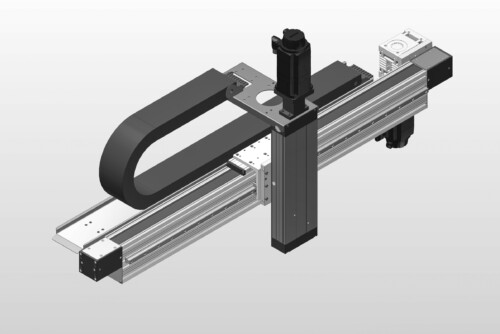

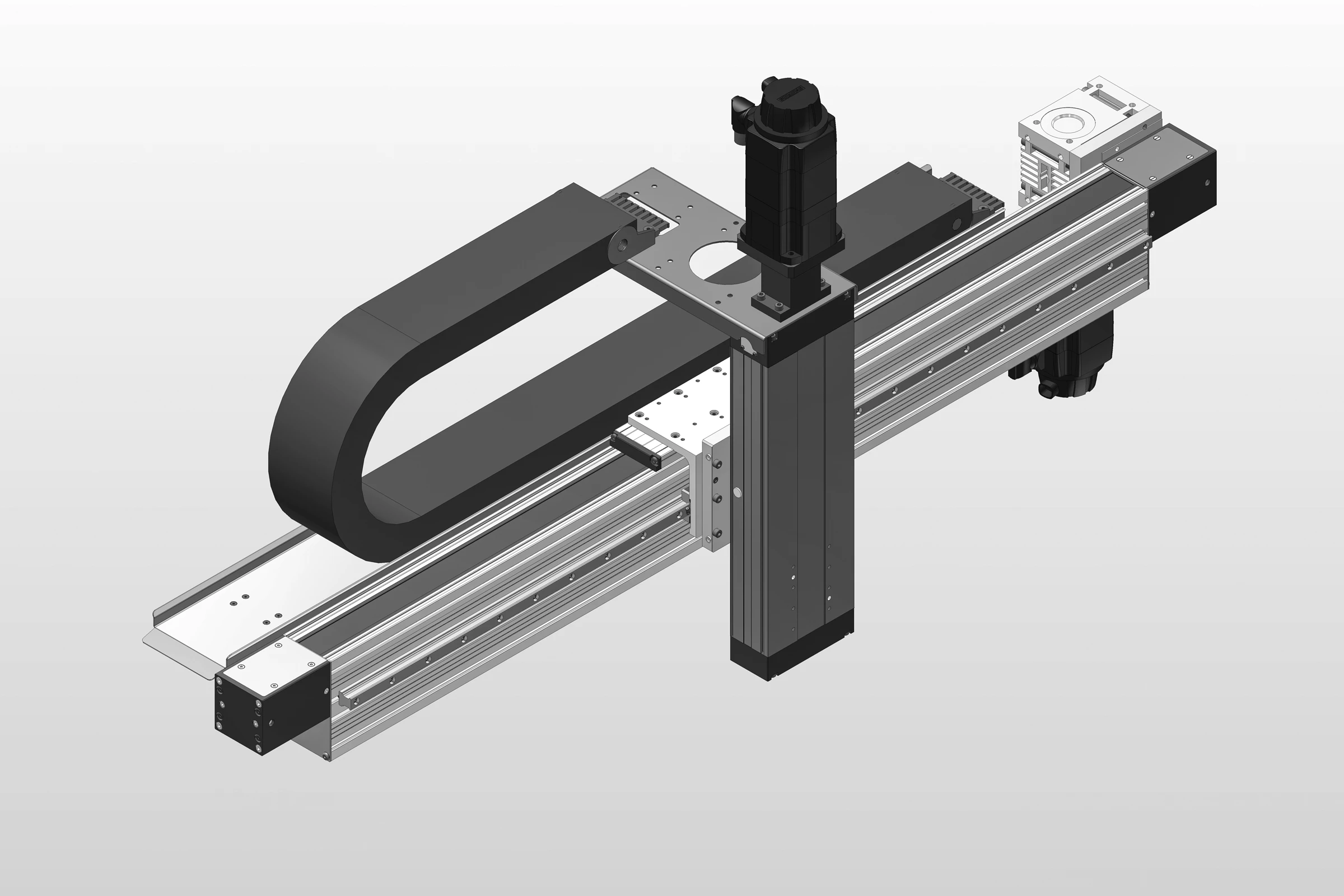

Dynamic modules DM

for highly dynamic applications with high loads and very fast cycle times

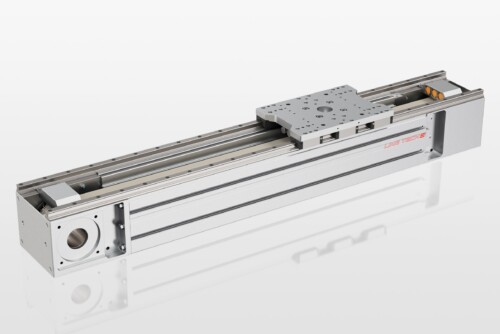

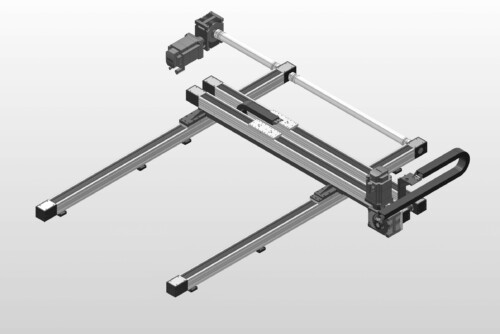

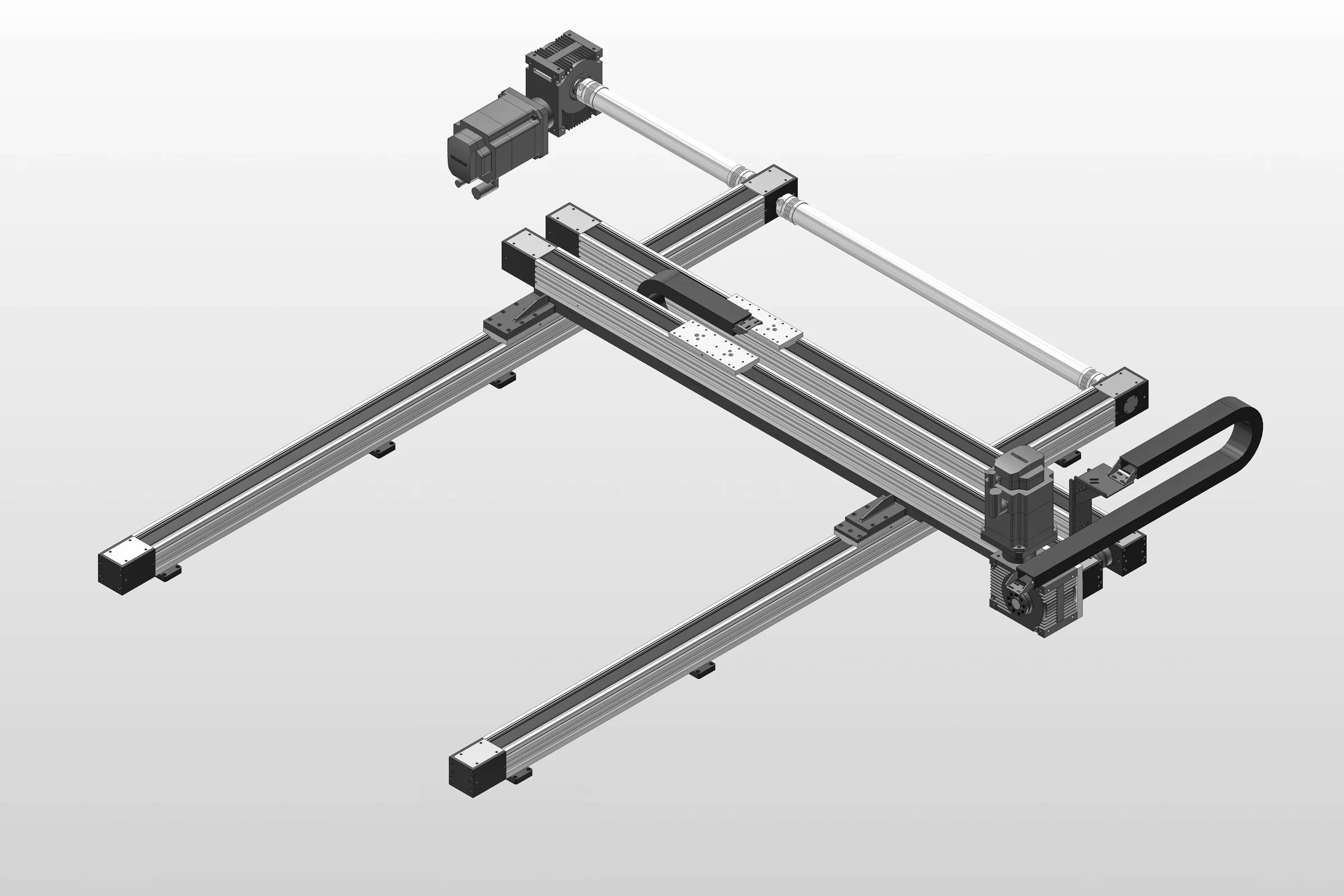

With toothed belt drive (Type DM…ZR…):

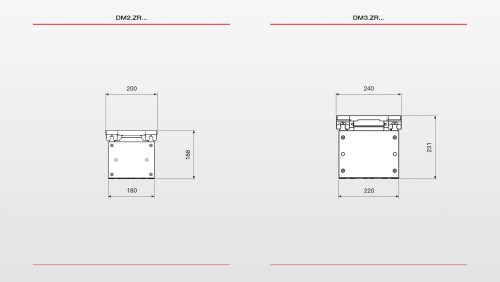

- 2 sizes

- Stroke up to 6360 mm

- XL version: Stroke up to 13'160 mm

- C0: 4500…7200 N

- vmax = 5 m/s | amax = 50 m/s2

- Repeatability <0.1 mm/1000 mm

- Positioning accuracy 200 µm/1000 mm

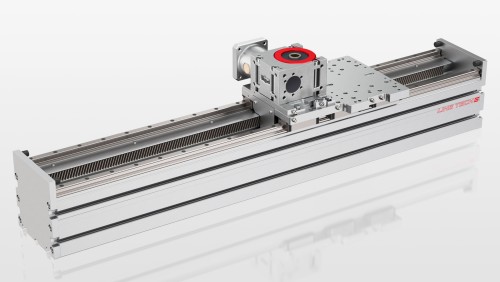

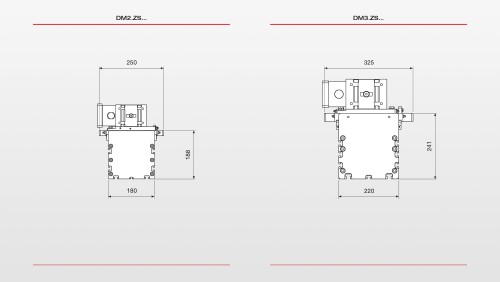

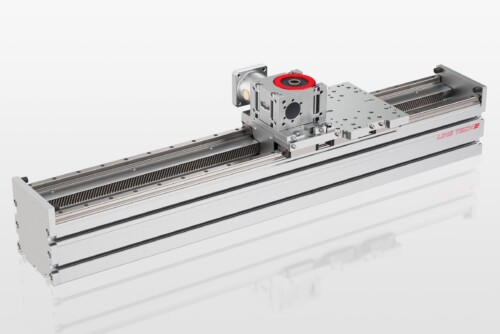

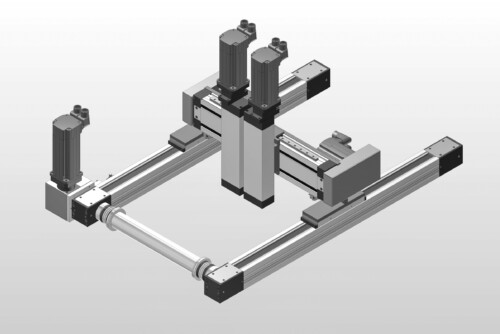

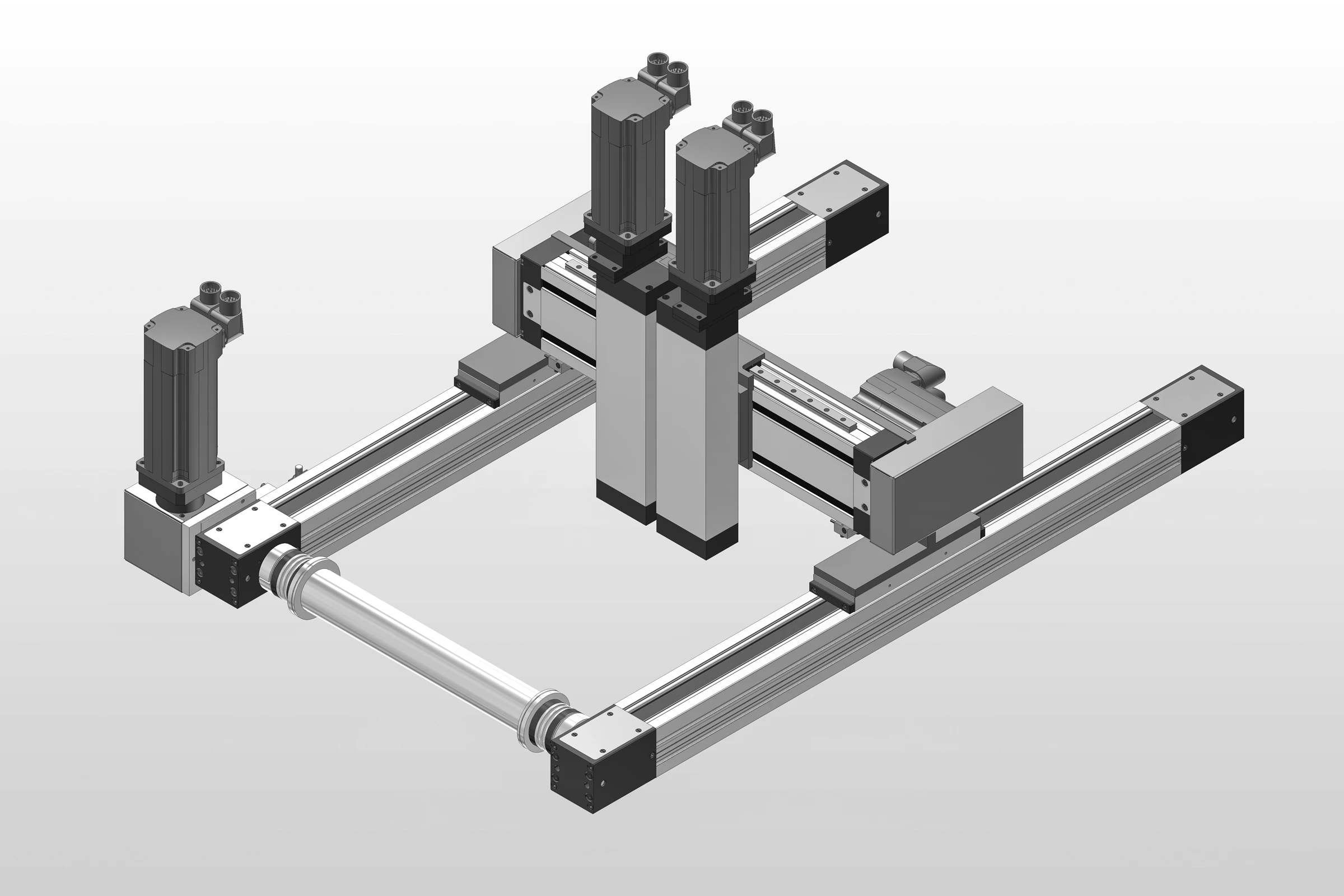

With rack and pinion drive (Type DM…ZS…):

- 2 sizes

- Stroke up to 5550 mm

- XL version: Stroke up to 19'150 mm

- vmax = 5 m/s | amax = 50 m/s2

- Repeatability < 0.04 mm/1000 mm

- Positioning accuracy 36/37 µm/1000 mm

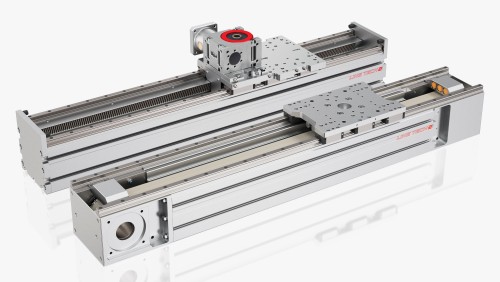

LINE TECH Dynamic modules DM

are designed for applications with high loads and very short cycle times. Thanks to the special design of the extruded aluminium profiles, the base carriers have very high torsional rigidity and are suitable as long-stroke, self-supporting axes. With two integrated linear rail guides with a total of 4 to 6 runner blocks as well as powerful drives via high-performance rack and pinions (DM...ZS...) or toothed belts (DM...ZR...), LINE TECH dynamic modules meet the highest demands in terms of load capacity, dynamics and service life. Two sizes (DM2 and DM3) are currently available.

Design and advantages

- Ready-to-install dynamic modules

- Torsion-resistant aluminium profile as base carrier

- Aluminium carriage

- Optimal movement characteristics, high load ratings and high rigidity due to two integrated, zero-play linear rail guides with a total of either 4 or 6 runner blocks

- Drive via either

- Toothed belt (DM…ZR…)

- Rack and pinion (DM…ZS…)

- Simple gearbox and motor mounting

- Design can be adapted to the application*

Documents

- DM Catalogue (PDF)

- Assembly/maintenance instructions DM…ZR (PDF)

- Assembly/maintenance instructions DM…ZS (PDF)

- Accessories (PDF)

- Calculation bases (PDF)

*Adaptations to meet specific customer needs can be realized flexibly and at short notice thanks to our JIT production facility – from minor additional processing to complete application-specific solutions.

Our customers always benefit from short delivery times thanks to our large warehouse with correspondingly high availability.

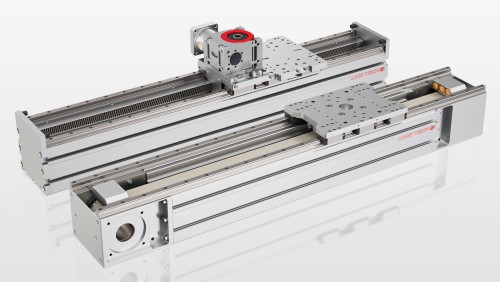

LINE TECH Dynamic module range

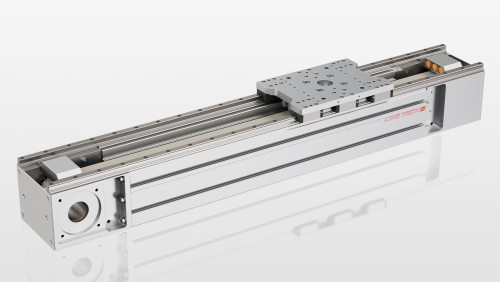

Dynamic modules with toothed belt drive

XL version for application-specific extra-long strokes of up to 13 metres. Even longer strokes available on request.

Dynamic modules with rack and pinion drive

XL version for application-specific extra-long strokes of up to 19 metres. Even longer strokes available on request.

Contact

- Contact your LINE TECH sales consultant » Contact

Application examples

In addition to the in-house development and production of linear axes, LINE TECH specializes in the conception, design and manufacture of multi-axis system solutions. Since 1993, we have been supporting our customers with engineering services and supplying application-specific optimized linear systems for a wide range of functions.