Ball bushings, precision shafts, grooved shaft guides, torque guides and roller guides

Precision shafts

Precision shafts

- Standard shafts

– Unfinished ends, ideal for individual further processing or cutting

– Flexible to shorten and adapt - Machined shaft

– Ready for installation, e.g. with face thread (on one or both sides), fitting shoulders or flange machining - – Customised finishing

- Factory lengths: up to 6000 mm

- Diameter: Ø 3–100 mm

- End machining: according to drawing/specification

- Materials

– X46Cr13 (1.4034): Stainless martensitic chrome steel, 52–60 HRC, corrosion-resistant, hygienic

– X90CrMoV18 (1.4112): High-alloy stainless tool steel, up to 58–60 HRC, acid and corrosion resistant, for special applications

– Cf53 (1.1213): Quenched and tempered steel, unalloyed, 59 HRC, for flame and induction hardening

- LINE TECH cutting and machining service for precision shafts

Documents (PDF)

Consulting

Ball bushings guides

Ball bushings and accessories

The tried-and-tested standard and special guide elements – precise and highly efficient:

- Standard and special ball bushings from ø3-150

- In normal and corrosion-resistant designs

- Particularly economical eco bushings

- Super ball bushings for high loads

- Ball sleeves with reduced cross-section

- Tandem, flange and tandem flange bushings

- Rotation bushings

- Housings for standard ball bushings

- Quad blocks

- LINE TECH cutting and machining service for precision shafts

Documents (PDF)

- LINE TECH Präzisionswellen-Kugelbuchsen-Linearkomponenten-Laufrollenführungen

- NB Slide Bush- Topball

- NB Storke Bush- Slide Rotary Bush

CAD data

- Kugelbuchsen (standard/short stroke/rotation/top ball)

Consulting

Grooved shaft guides

Grooved shaft guides

Grooved shafts can be combined with a wide range of nut designs – for flexible assembly and design options:

- Commercial-grade grooved shafts (non-ground)

Economical solution for simple requirements - Standard grooved shafts

For common applications with good dimensional accuracy - Ground grooved shafts

Highest surface quality for precision applications

Nut types for grooved shaft guides

- SSP: Cylindrical nut with keyway

- SSPM: Cylindrical nut without keyway

- SSPF: Flange nut – easy installation with high stability

- SSPT: Double-sided milled flange nut for compact design

Rotary groove guides for applications with combined rotary and linear motion

- SPR: Cross roller bearings – extremely high rigidity and positioning accuracy

- SPB: Ball bearings – quiet, smooth running under high loads

Documents (PDF)

Consullting

Torque shafts with flange nuts

Torque guides – Backlash-free precision with maximum stability

Precise linear motion with reliable torque support – ideal for applications that require anti-rotation protection in addition to linear motion. Versions with ball or roller technology.

- Torque shafts, drawn

High-precision, drawn profile shafts with special drive geometries – ideal for anti-rotation linear movements. - Torque flange nuts

Compact guide elements with integrated anti-rotation device – matching the groove contour of the shaft. Available in various designs and materials for standard and special applications.

Thanks to modular design and a wide range of combinations with drive elements, we offer customised solutions for demanding motion tasks – from automation technology and test benches to medical technology and special machine construction.

Documents (PDF)

CAD data

Consulting

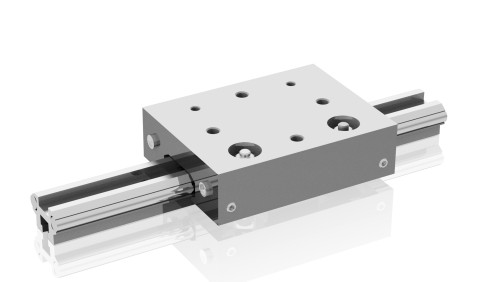

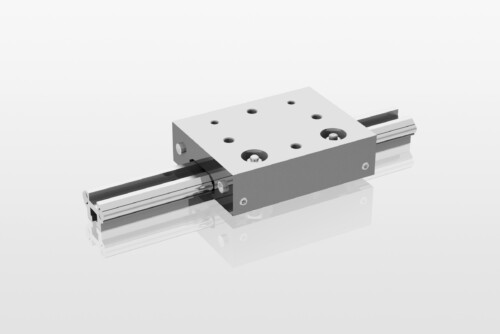

Roler guides

LINE TECH roller guides – fast and precise

- Excellent guidance accuracy and smooth running

- Maximum speeds and accelerations

- Low mass and minimal rolling friction

- Good load-bearing capacity for forces and torques

- High operational reliability thanks to robust design

- Insensitive to dirt

- Sizes 25…54

- Normal and corrosion-resistant design

- Rail lengths up to 3.75 m (longer on request) and widths from 20 to 52 mm

- Rollers and pivots; sizes 25…64

- Available with integrated measuring system

- LINE TECH Cutting and machining service for rail guides

Documents (PDF)

Consulting